Just the base trunk:

Wrap around top branches with leaves:

Whole tree (and one green butterfly lol)

It surprises me, really, how much use I get out of those sample sizes of paint. This is at least thre or four projects now just picking up a couple here and there.

And I'm thrilled that my kids got interested in this- they helped with the painting and are helping with the rack construction/staining too.

We figure, in our house, everybody gets to help out a bit so they learn how. That way my kids know HOW to do basics for themselves when they leave the nest. Or they know just how to figure out where to find the answers to get it accomplished.

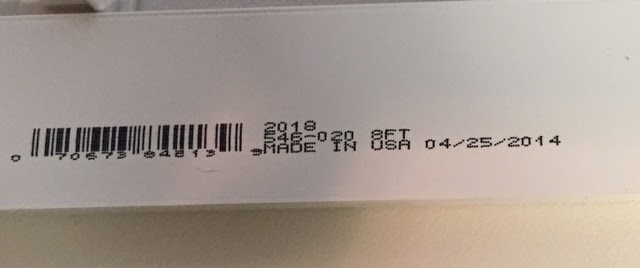

Anywhoo, I've started with the staining process too.. Top to bottom it goes: (top) one coat stain + pre-stain, (middle) just pre-stain, and (bottom) untreated.